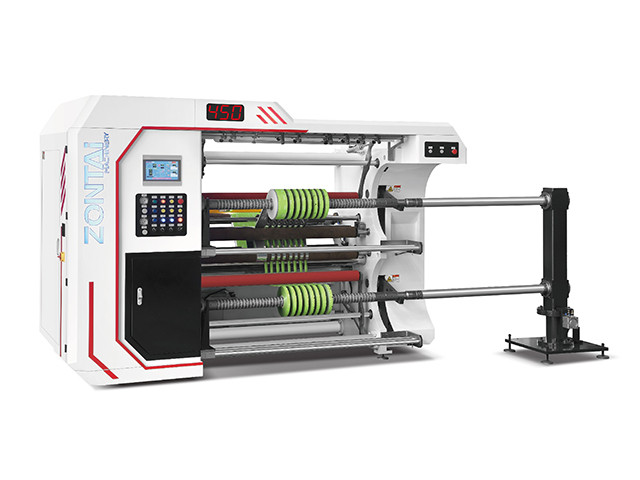

Features:

1, Unwinding unit: Shaftless auto loader;

LPC for tracking both edge and printing marks,

Unwinding tension through magnetic brake and loadcell for close-loop auto tension.

2, Slitting Unit: 10 sets of razor knives

3, Rewinder shaft: 3inch friction shafts.

4, Rewind tension: proportional valves controlled.

5, Rewinder pressure unit: pressure rubber roller controlled by air cylinder

6, Waste edge processing section: blowing fan included.

7, Electrostatic elimination Unit: install in up and down rewinder part

8, Finished Produce unloading Unit: discharge rack

9, PLC control system: Siemens PLC and touch screen.

Main technical parameter:

|

Jumbo roll width |

1000mm |

1300mm |

|

Diameter of roll |

800mm |

800mm |

|

Diameter of rewinding |

600mm |

600mm |

|

Inner dia.of paper core |

3''(6'') |

3''(6'') |

|

Slitting speed |

10-400m/min |

10-400 m/min |

|

Tolerance of EPC |

-0.1mm |

-0.1mm |

|

Min.width of produce |

50mm (30mm) |

50mm (30mm) |

|

Total power |

12KW |

12KW |

|

Weight |

3800Kg |

4000kg |

|

overall dimension (LxWxH) |

2.2mx4mx2.1m |

2.2mx4.3mx2.1m |

Optional device:

1, 6inch rings for rewinder shaft

2, auto push device for rewinder rolls

3, trimming edge rewinder machine